Key Takeaways

The role of high-speed hand tools in specialized tasks must be considered due to their precision and efficiency.

Familiarizing oneself with safety practices is critical to ensure a risk-free environment while operating high-speed tools.

Maintenance of these tools is integral to uphold performance and extend their lifespan.

Staying updated with the latest technological advancements is beneficial for optimizing performance and anticipating future trends.

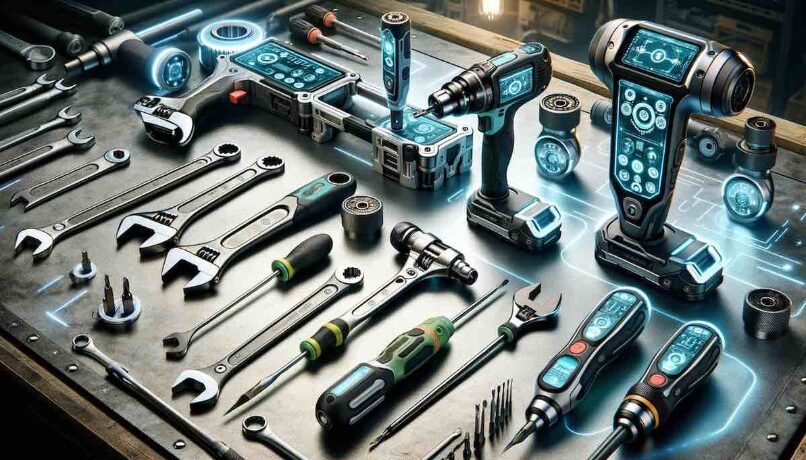

Within the buzzing atmosphere of modern workshops, the symphony of high-speed hand tools can be heard, marking the progress of intricate projects and precision work. One tool that stands out is the pneumatic router, notable for its agility and precise control. Integrating such sophisticated equipment into fabrication processes significantly upgrades traditional methods. It signifies a transition to more streamlined, accurate production techniques that honor artisans’s time-honored skills while harnessing modern technology’s power.

Revolutionizing Precision: The Benefits of High-Speed Hand Tools

The conventional toolkit of workshops has been revolutionized with high-speed hand tools, propelling industries forward with exceptional performance. Artisans across various fields rely on them for their capability to execute precise and refined tasks, which is crucial in sectors such as woodworking, metal fabrication, and automotive work. Their speed and accuracy substantially reduce the margin of error, facilitating impeccable execution of designs with outstanding sophistication. Moreover, these tools champion efficiency, completing tasks at a pace that manual labor cannot achieve, thereby accelerating project timelines and boosting productivity significantly.

Safety First: Essential Practices for Using Hand Tools at High Speeds

Despite their benefits, high-speed hand tools demand a considerable emphasis on safety routines to prevent workplace injuries. This is not just about wearing the proper protective equipment; it’s also about being aware of the operational nuances that each high-speed tool entails. For instance, ensuring that tools like the pneumatic router have safety guards before operation can prevent potential mishaps. Workshops should provide comprehensive training to all users of high-speed tools, focusing on machine-specific safety protocols and emergency response procedures. This knowledge helps create a secure environment conducive to productive and uninhibited craftsmanship.

Efficiency on the Go: How High-Speed Hand Tools Optimize Workflow

High-speed hand tools emerge as a critical solution when deadlines are pressing, and quality cannot be compromised. The speed at which they operate not only expedites project completion but also ensures a level of perfection that builds reputation and client trust. A high-quality pneumatic router, for instance, maintains its precision with each cut and carve, resulting in uniformity and consistency that is essential for large orders or repetitive patterns. The result is a harmonious workflow where efficiency and quality coalesce, enhancing the craftsman’s overall work experience and client satisfaction.

The Art of Maintenance: Keeping Your High-Speed Hand Tools in Top Shape

Among the crucial aspects of owning any machinery is the commitment to its upkeep. High-speed hand tools are no exception. Their efficiency and longevity hinge significantly on regular and thorough maintenance. This includes cleaning to prevent the build-up of materials that could compromise the tool’s function, lubrication to maintain smooth operation, and inspection for worn components that could hamper performance or safety. Skimping on these practices can lead to breakdowns, work disruptions, and added costs. A meticulous approach to maintenance not only prolongs the tool’s life but also ensures that it runs at optimum capability, providing reliable service even under rigorous usage.

Innovation in the Industry: Recent Developments in Hand Tool Technology

Innovation in high-speed hand tool technology points to a bright future for various industries that rely on precision and efficiency. The sector has seen the introduction of more sophisticated and user-friendly models that promise enhanced performance and greater comfort and safety for the operator. Materials science has played a pivotal role in this evolution, with newer, lighter, yet more durable materials being used to construct these tools. Innovations like the brushless motor have redefined tool longevity and power output standards. These advancements contribute significantly to workplace efficiency and create a new blueprint for what professional-grade equipment can offer, as outlined in industry analyses.

Hand Tools Selection: Choosing the Right Equipment for Your Project

Selecting the perfect high-speed hand tool involves understanding the project’s needs and recognizing the device’s specialties. It’s a fundamental decision that influences the final output of any workpiece. The breadth of available varieties, from general-purpose items to specialized equipment such as a precise pneumatic router, necessitates careful consideration of the project’s material, scope, and intricacy. With many options available, consulting with industry experts, reading up on the latest tool reviews, and even testing tools before purchase can lead to better-informed decisions that synthesize perfectly with the intended application.

Environmental Considerations: The Ecological Impact of Hand Tool Use

With the urgent need for environmental stewardship, the ecological impact of high-speed hand tools is not to be ignored. Fortunately, initiatives within the industry have centered around the design of energy-efficient models that minimize carbon footprints without compromising performance. The push towards sustainability has not omitted any facet of tool design—from battery production to the eventual recycling of tools, considerable efforts are underway to ensure that these devices tread lightly on the earth.

Pneumatic tools, which use compressed air as a power source, offer a relatively benign environmental profile compared to fossil fuel-derived electricity, highlighting their role in a more sustainable future.

Looking Ahead: The Future of Hand Tools in the Digital Age

The emergence of the digital age heralds an exciting chapter for the hand tools industry. As innovative technology becomes more prolific, incorporating digital features into hand tools is imminent. With advancements such as the Internet of Things (IoT), users can soon monitor their tools’ performance, wear and tear, and energy efficiency in real-time. Educating oneself about such possibilities is not just about keeping pace with technology—it’s about embracing an era where hand tools are not only practical instruments but also nexuses of data and digitization.

This predictive maintenance capacity, underscored by data analytics, could redefine the usability and longevity of hand tools, aligning with the forward trajectory of industry practices as discussed in scientific research.